Why discard what still works? Many machines have been providing reliable service for decades - they are often in excellent mechanical condition, but are no longer technically up to date. New control systems, smart sensors and stricter safety requirements pose the question for many companies: replace or retrofit?

The answer is often: retrofit.

Retrofitting existing machines is not only economically attractive, but also sustainable. Instead of scrapping a functioning system, it is equipped with modern electronics, new safety technology and intelligent diagnostic options - and thus remains competitive in the age of Industry 4.0.

What does retrofit actually mean?

The term retrofit comes from the English language and means retrofitting or modernising.

In mechanical engineering, retrofitting describes the technical upgrading of existing systems in order to adapt them to current requirements - whether in terms of productivity, energy efficiency or safety.

Retrofit is more than just a repair: while a defect is rectified during a repair, retrofit brings new functions into the system. You could say: old becomes smart.

Examples:

- Replacing classic relay technology with modern safety control systems.

- Modernisation of isolating protective devices with modern safety switches and sensors

- Integration of digital diagnostic interfaces that simplify monitoring and enablepredictive maintenance.

This turns yesterday's machine into a system for tomorrow.

Retrofit in mechanical engineeringWhen old meets new

Retrofitting is a real perennial favourite, especially in mechanical engineering.

Many companies operate systems that are mechanically robust but outdated in terms of control technology. New machines would be expensive, often even unnecessary - because the solid basis is already in place.

The advantages are obvious:

- Cost efficiency:

Retrofitting often costs only a fraction of a new purchase. - Sustainability:

Existing resources continue to be utilised. - Production reliability:

Downtimes are minimised.

However, every change to a machine also presents a new challenge: the safety technology must also be brought up to the current state of the art.

Machine safety during retrofittingSafety has priority

Anyone retrofitting a machine must also check and adapt its safety functions. This is because, according to the Machinery Directive, any significant change practically turns an existing machine into a new one - with all the requirements for risk assessment, CE labelling and conformity with standards.

A classic example: An old press is fitted with a new safety controller. This may change the reaction times of the individual safety functions. These must then be re-evaluated, including all safety components such as switches, guard locking devices or safety relays.

In this context, many operators rely on so-called grandfathering - i.e. the assumption that older machines can continue to be operated as long as they were once standard-compliant.

However, as our colleague explains in the video "Grandfathering", this is a dangerous misconception.

In practice, there is no such thing as grandfathering. This means that every modernisation requires a new safety assessment.

Modern systems - such as the Smart Safety System from BERNSTEIN - make it possible to modernise existing machines and systems quickly and easily. They combine classic safety with digital communication and provide valuable diagnostic data for predictive maintenance and condition monitoring.

This makes retrofitting not only safe, but also intelligent.

Retrofit meets Industry 4.0Digitalisation as a door opener

The future of retrofitting lies in networking.

Sensors and switches are no longer only used to prevent hazards, but also to collect data. This opens up new possibilities:

- Status data indicates when components need to be serviced.

- Error messages can be read out directly on a PC or smartphone.

- Retrofitting is becoming the gateway to digital production.

The Smart Safety System from BERNSTEIN shows how this works:

Safety components such as electronic safety sensors, guard locking devices or emergency stop switches communicate in series with an intelligent safety evaluation system. This transmits the data to PC software or a higher-level control system, which displays the status of the system in real time - even for older machines.

Retrofit thus combines the best of both worlds: robust mechanics and modern intelligence.

Our practical example:The best of the 90s and the hits of today

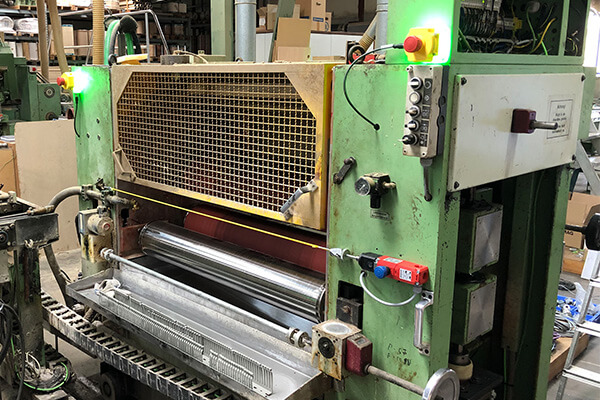

Our application report "The best of the 90s and the hits of today" shows what retrofitting looks like in practice.

In it, a laminating system from the 1990s is equipped with modern safety technology from BERNSTEIN - without changing its basic design.

The result:

- The system fulfils current safety standards.

- Productivity is maintained.

- New diagnostic functions make maintenance plannable.

A successful example of how retrofitting not only creates safety, but also sustainability - in the spirit of "upgrading instead of throwing away".

Conclusion: Retrofit is future-proofing with security

Retrofitting means preserving the tried and tested while integrating the new.

For many machines, retrofitting is the most economically and ecologically sensible way to make the leap into Industry 4.0. Modern safety technology ensures that this modernisation does not take place at the expense of safety - but actually improves it.

Whether through smart safety gate switches, safety relays or the Smart Safety System - BERNSTEIN shows how machines can be made safe, efficient and digitally fit for the future.

Are you planning a retrofit or would you like to know how to modernise your machines safely?

Our safety technology experts will be happy to help - from analysing and selecting the right components to integration.

Get in touch now →