Safety relays and safety controllersEvaluate, switch, protect – for the highest safety requirements

Reliable monitoring, secure evaluation, flexible integration: safety relays form the heart of every functional safety solution.

With BERNSTEIN's classic, programmable and diagnostic-capable safety evaluations, you can secure inputs and processes up to Performance Level e – compliant with EN ISO 13849-1 and prepared for modern interfaces such as IO-Link, USB or NFC.

Our solutions integrate seamlessly into existing safety chains and ensure reliable safety in machines and systems – exactly where failures are not an option.

What is a safety relay?A building block for genuine safety

Safety relays play a central role in the functional safety of machines and systems. They detect signals from sensors, switches or emergency stop devices and ensure that a quick and reliable response is provided in the event of an emergency – for example, by selectively shutting down a drive.

Unlike standard relays, they meet the high requirements of EN ISO 13849 or IEC 62061. They detect internal faults, prevent unsafe conditions and thus make a decisive contribution to compliance with the required performance level (PL d or PL e).

Whether classic, programmable or with diagnostic functions – BERNSTEIN offers safety relays for every safety-related application. With modern interfaces such as IO-Link, USB or NFC, our evaluation modules can be integrated flexibly and future-proof.

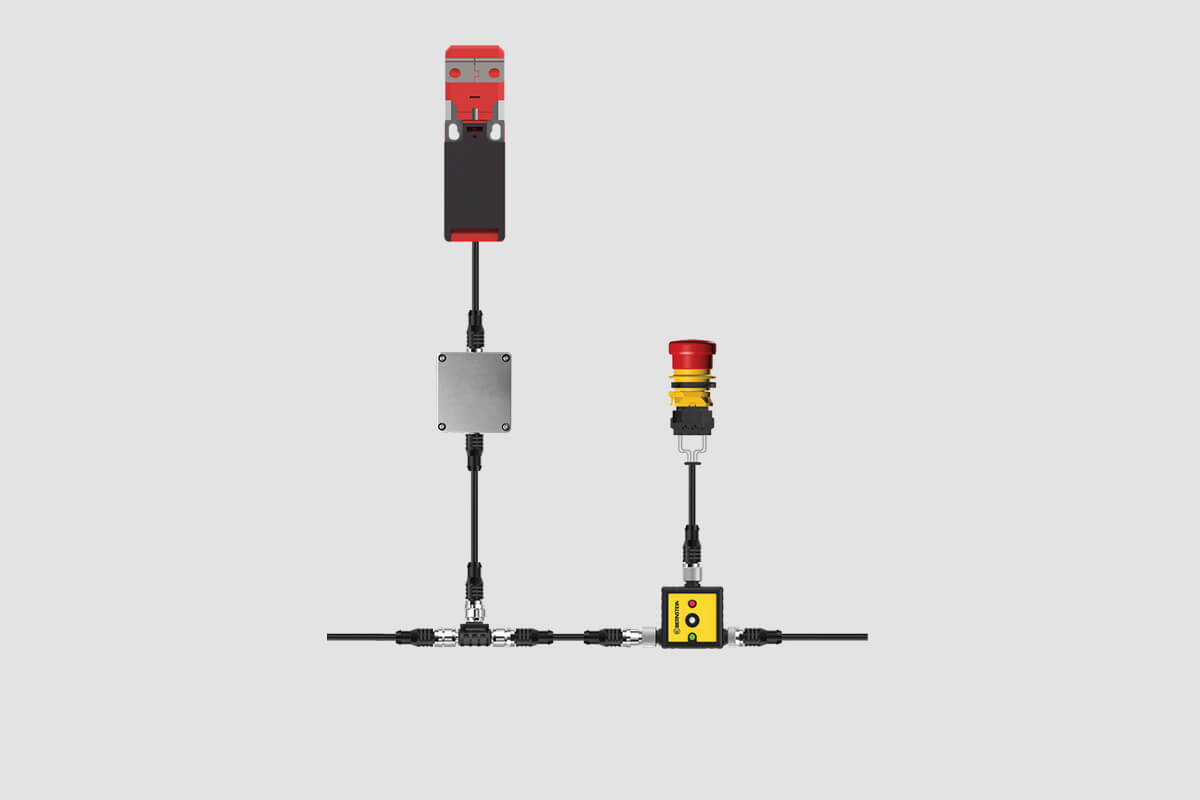

Intelligent status evaluation in series connection

Can be integrated into the Smart Safety System

for the integration of mechanical components

Scalable according to requirements

Free of charge, easy and quick to configure

Safety relays and safety controllers for every applicationFlexible application – from standard to networked

Whether proven standard functions, flexible control or intelligent interfaces – our safety relays and safety controllers adapt to your application. Depending on the safety architecture, machine complexity or diagnostic requirements, we offer solutions that can be seamlessly integrated into your control system – reliable, scalable and certified up to PL e.

Every task has its solutionThe right safety relay for every application

| Feature | Safety relays | Intelligent safety relay | Configurable safety relay | Expandable safety controller |

| Function | Classic signal evaluation | OSSD evaluation, diagnostics & IO-Link | Configurable safety functions | Expandable with DCD diagnostics |

| Connectable devices | 1 | up to 32 with DCD | up to 64 with DCD | up to 394 with DCD |

| Safety inputs | 2 | 2 | 10 | up to 154 |

| Safety outputs | 1 relay | 1 relay with 3 contacts | 2 relays with 3 contacts | up to 68 |

| Interfaces | – | IO-Link, USB and NFC | Profinet, Ethernet/IP, Modbus/TCP and USB | Profinet, Modbus/TCP, USB and EtherCAT |

| DCD-compatible | X | ✔ | ✔ | ✔ |

| Configurable via software | X | X | ✔ | ✔ |

| Expansion modules | X | X | X | up to 8 I/O expansion modules |

Safety relays in practical useProven solutions for real-world applications in machines and systems

Applications SMART Safety System

The best of the 90s and the best of today

Retrofit of a laminating system from the 1990s with the latest BERNSTEIN safety technology.

Applications SMART Safety System

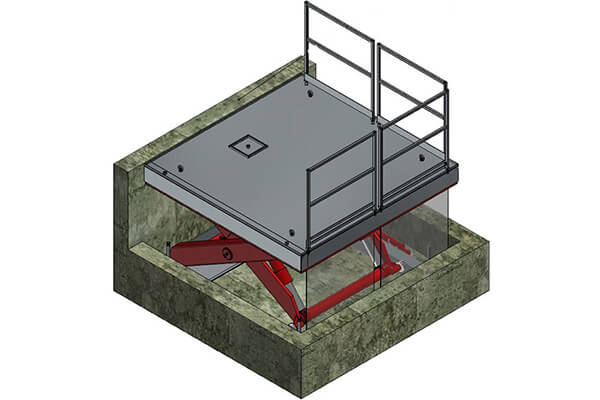

Reaching high at the airport - not only on the runway

A loading platform at the cargo terminal of a german airport was equipped with SMART Safety from BERNSTEIN

Applications SMART Safety System

Smart safety technology for the waste disposal industry: Our SRF non-contact safety sensors check whether maintenance flaps are properly closed.

Strong in function and detailRelay solutions from BERNSTEIN

For decades, BERNSTEIN has stood for safe, well-designed solutions in machine and plant engineering. Our safety relays perform key tasks in functional safety – they evaluate signals, monitor conditions and ensure targeted shutdown in the event of danger.

Whether classic, diagnostic-capable or freely configurable: our relay solutions are designed for a wide range of applications – from simple individual applications to networked safety architecture with DCD. Technically precise, reliable in operation and compliant with standards up to Performance Level e.

- Decades of experience

in functional safety technology - Wide product range:

from classic relays to expandable safety controllers - Diagnostic-capable systems

with IO-Link, USB, NFC and DCD - Easy integration

into different machine and control concepts - Scalable

for simple, complex or retrofittable applications - Compliant with standards

up to Performance Level e according to EN ISO 13849 - Personal project support

from experienced application experts

A safety relay is specially designed to perform safety-critical functions in machines and systems – such as evaluating an emergency stop signal or shutting down dangerous movements when a safety door is opened. Unlike a standard relay, which merely switches, a safety relay has additional measures for fault detection, redundancy and self-monitoring. This enables it to meet the functional safety requirements of EN ISO 13849 or IEC 62061.

BERNSTEIN safety relays meet the functional safety requirements of EN ISO 13849-1, EN 61508 and EN 62061 – depending on the product, up to Performance Level e (PL e). For international use, our products are equipped with relevant certifications, including cULus, CCC and PI-certified interfaces for PROFIBUS and PROFINET.

The specific conformities can be found in the respective technical documentation.

Performance Level e (PL e) is the highest classification in functional safety according to EN ISO 13849-1. It describes the reliability of safety-related control functions.

→ You can find a detailed explanation of this in our wiki article: Performance Level in safety applications

A programmable safety evaluation is useful when several safety-related components need to be flexibly combined and reliably evaluated.

With the specially developed software from BERNSTEIN, safety circuits for the SCR P or SCx can be conveniently created, simulated and adapted using drag & drop. This saves time in project planning and enables quick commissioning – especially for more complex applications.

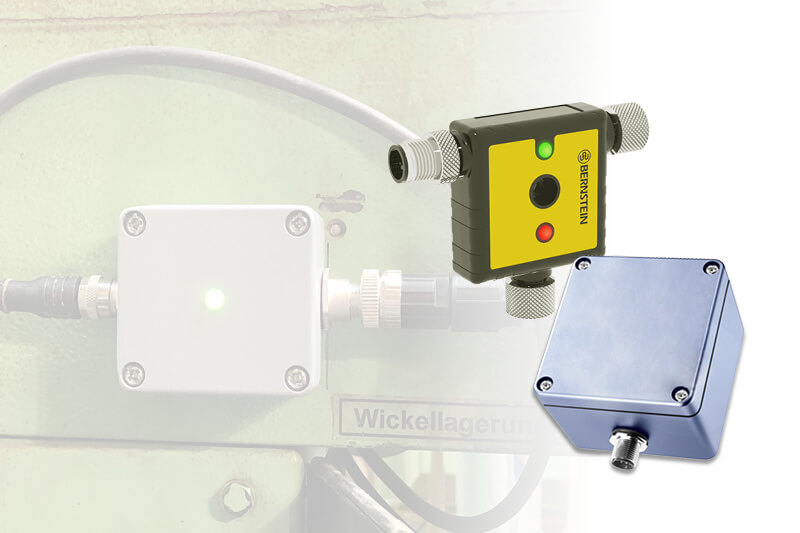

DCD (Daisy Chain Diagnosis) is an intelligent, patented diagnostic system from BERNSTEIN. It enables the transmission of detailed status and error messages from all connected safety components within a series connection – clearly, centrally and efficiently.

→ More about how it works in the Wiki: What does ‘Daisy Chain Diagnosis’ mean?