Designed to Stop. Built to Protect.Emergency stop devices from BERNSTEIN

Protecting people, machines, and productivity – with BERNSTEIN emergency stop devices.

Emergency stop devices are critical components in industrial safety systems. Whether as pushbuttons or rope pull switches – our solutions comply with international standards such as EN ISO 13850 and ensure reliable machine shutdown in hazardous situations.

Discover how BERNSTEIN combines robust design, fail-safe functionality, and easy integration to meet the safety needs of modern production environments.

Jump directly to the right place:

Areas of application | Comparison of switch types | Advantages | Contact

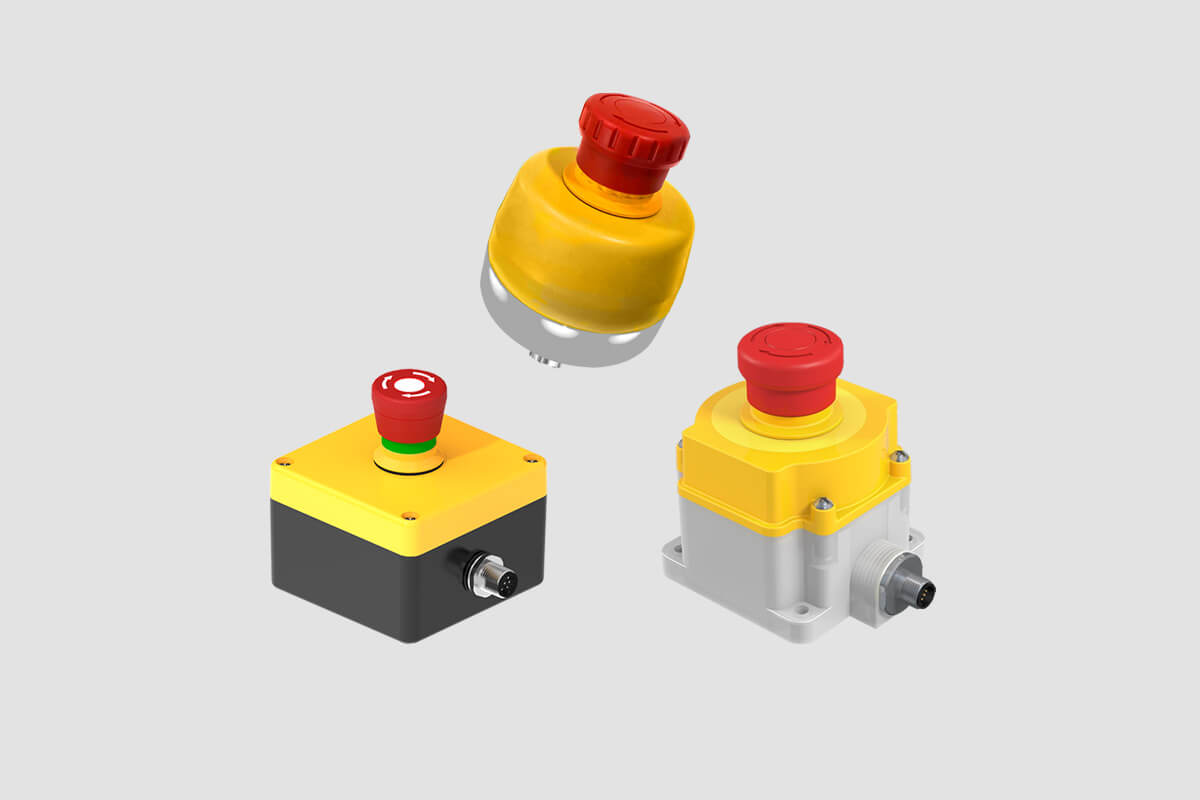

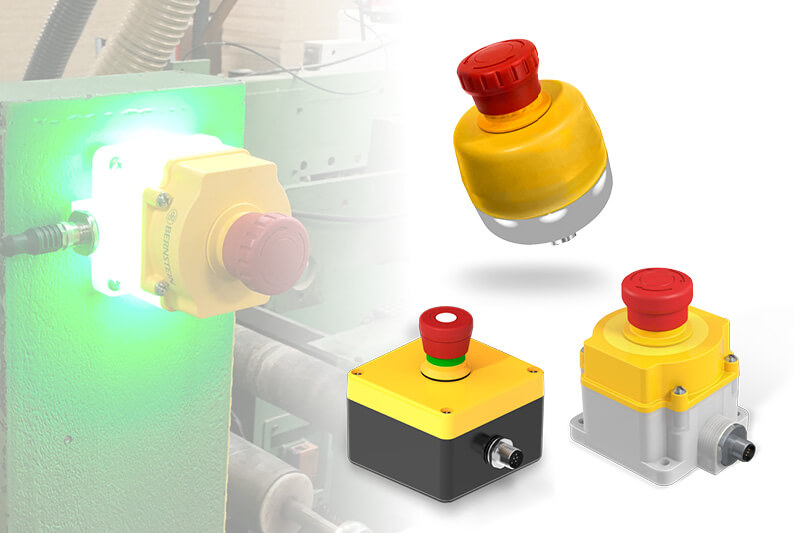

Safety comes in many variantsTypes of emergency stop devices and switches offered by BERNSTEIN

Different machines, different risks – but one goal: stopping safely when it matters most. That’s why BERNSTEIN offers a carefully engineered range of emergency stop devices and switches tailored to real industrial needs.

Whether space-saving pushbuttons or full-length rope pull switches – each solution is built to perform reliably in demanding environments and to simplify safety by design.

Because in safety, the right choice isn’t just technical. It’s essential.

Safety looks different in every applicationChoosing the right emergency stop switch

| Feature | Emergency stop pushbuttons | Safety rope pull switches |

| Typical application | Control panels, safety fences, machine enclosures | Production lines, conveyor systems, elongated machines |

| Activation method | Direct push (manual actuation) | Pull wire and rope break |

| Actuation range | Point-specific (local) | Along cable length (up to 75 m) |

| Reset function | Mechanical manual reset | Mechanical manual reset |

| Mounting type | Panel-mount, surface or machine-frame mount | Surface or machine-frame mount |

| Variants | Illuminated body, LED indication | With / without tension monitoring, robust housing, angled housing |

| Environmental resistance | IP65–IP67 depending on model | IP65–IP67, vibration- and impact-resistant |

| Standards compliance | EN ISO 13850, IEC 60947-5-5 | EN ISO 13850, IEC 60947-5-5 |

Conveyor systems

Safety over distance

Conveyor systems rarely stop, but safety must.

Wherever goods move quickly and access is limited, reliable emergency stop coverage becomes essential.

BERNSTEIN’s rope pull switches extend safety along the entire length of the line, so that a stop is never more than an arm’s reach away.

Built to withstand daily wear and harsh conditions, they bring peace of mind to environments where speed meets responsibility.

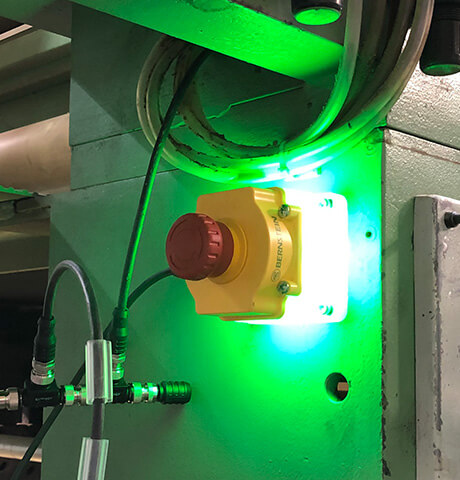

Existing workstations

Retrofit safely

Production lines are rarely uniform — especially when older machines meet modern automation.

That’s where flexible safety solutions matter.

In a retrofit of a 1990s laminating machine, BERNSTEIN emergency stop devices were integrated without compromise: safety upgraded, functionality preserved.

This kind of adaptability shows that safety doesn't have to start from scratch — it just needs the right components.

Industrial plant safety

Control at critical moments

Some areas demand more from every component — heat, dust, movement, or limited visibility are part of daily operation.

In such conditions, emergency stop systems must function without hesitation.

BERNSTEIN devices are built for exactly that: tough environments, fast access, and reliability when it matters most.

Because safety shouldn’t depend on ideal conditions.

Built for the demands of safety-critical decisionsAdvantages of using BERNSTEIN emergency stop devices and switches

When safety is part of the design from the start, every detail matters.

BERNSTEIN emergency stop devices combine decades of experience with practical engineering – delivering real benefits where reliability and responsibility go hand in hand.

Key advantages at a glance:

- Certified safety

All devices comply with international standards such as EN ISO 13850 and IEC 60947-5-5 – enabling fast, confident certification. - Robust, industrial-grade design

Resistant to vibration, dust, moisture, and mechanical stress – ideal for demanding environments. - Reliable performance – over time

High mechanical life expectancy and consistent function reduce maintenance and downtime.

- Developed in Germany

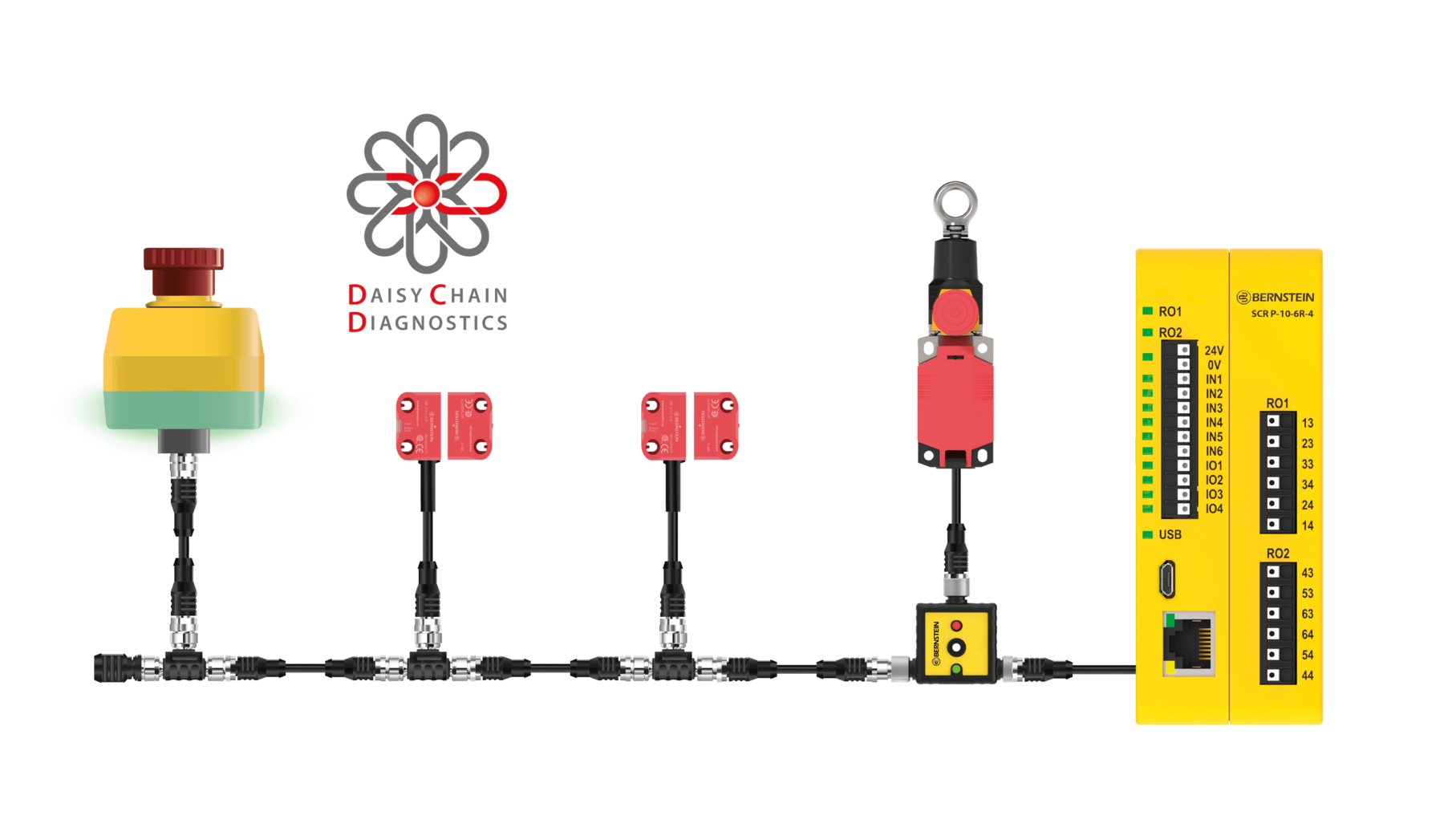

With technical expertise, industry experience and the ambition to make safety better. - Integration into the SMART Safety System

The BERNSTEIN Smart Safety System combines individually selectable components into an intelligent overall system - flexibly expandable, easy to integrate and ready for future requirements. - Intelligent fault diagnostics

The daisy chain diagnostics system (DCD) allows sources of faults to be recognised immediately - directly on the affected device, without time-consuming troubleshooting.