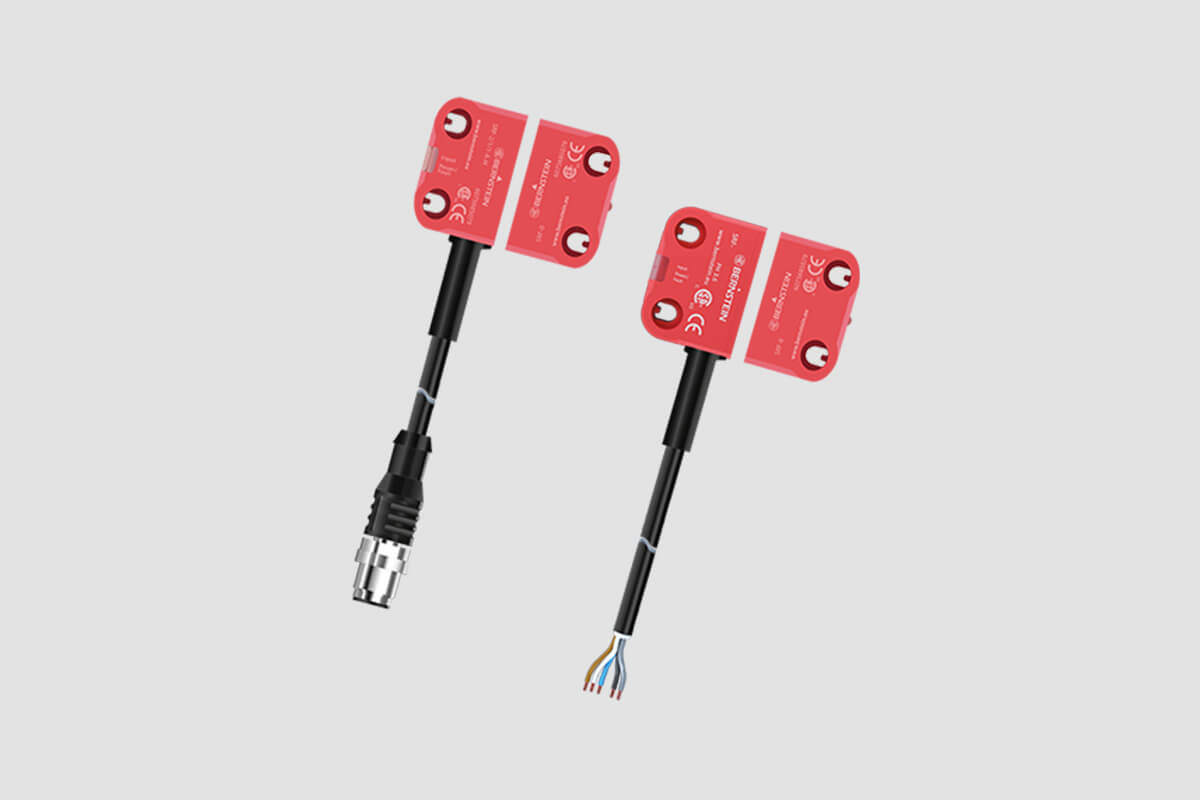

Safety switches and sensors from BERNSTEINSecure, lock, monitor. For smooth processes and maximum protection.

They lock flaps, monitor hoods, keep safety doors closed – and ensure that only safe operations are carried out. Safety switches and sensors from BERNSTEIN secure access to machines and systems – precisely, reliably and accurately.

Whether mechanical or electronic, with interlocking or contactless: our switches intervene when it matters – and stay out of the way when everything is fine.

For smooth processes and safety that thinks for itself.

What is a safety switch?Reliable guardians – designed for emergencies

Whenever machines are in motion, control is required – especially at doors, flaps and hoods.

Safety switches perform precisely this task: they check whether an access point is closed – and only release the process when everything is secure.

Unlike conventional switches and sensors, they are certified machine safety components – developed to protect both people and technology.

Whether with interlocking, for example for trailing saw blades, inductive for contactless detection or robust as a mechanical position switch:

The right solution depends on the location of use – but one thing remains the same: the safety promise.

Status signalling, early fault detection

RFID, coded variants

with high performance level

Maximum flexibility in mounting and application

for different requirements and safety concepts

e.g. doors, flaps and bonnets

e.g. robot cells and automated production lines

e.g. sawing, milling and pressing

Compact, hygienic applications

for long distances and decentralised access

Safety switches for every challengeTechnology that adapts to your processes

Safety switches are available in many designs - but not all of them are suitable for every machine. Different risks, motion sequences and environmental conditions require different technologies.

That's why BERNSTEIN offers a wide range of safety switches that are precisely tailored to your application: mechanical, electronic, non-contact or with guard locking.

For protection that not only works - but also fits your machine perfectly.

Every task has its solutionAn overview of the functions and features of our safety switches

| Feature | Electronically | Magnetic | Inductive | Separate actuator | With locking device | Rotatable |

| Actuation | RFID transponder | Magnetic (coded) | Metallic target | Separate actuator | Separate actuator | Integrated |

| Type of operation | contactless | contactless | contactless | mechanically | mechanically | mechanically |

| Switching element | Electronic outputs: OSSD | Reed switches | Electronic outputs: PNP | Electromechanical switching contacts | Electromechanical switching contacts | Electromechanical switching contacts |

| Rated operating voltage | 24 VDC | 24 VDC | 24 VDC | 24 VDC, 240 VAC | 24 VDC, 240 VAC | 24 VDC, 240 VAC |

| Diagnostic capability | DCD diagnosis/PNP output | - | - | Additional contact | Additional contact | Additional contact |

| Tamper protection | High coding | Low coding | - | Low coding | Low coding | n/a |

| Special features | Safe up to PL e, series connection possible, wear-free, LED status display | Easy to clean, conditional tolerance for misalignment | Safe up to PL d, additional safety evaluation required | Rotary switch head, slim design, up to 3 contacts | Rotatable switch head made of metal, robust | Safety switch integrated directly into the door hinge, no additional actuator required |

| Protection class | IP69 | IP67 / IP69 | IP67 | IP65 | IP67 | IP66 / IP67 / IP69K |

| Enclosure material | Plastic | Plastic | Nickel-plated brass | Thermoplastic, glass fibre reinforced | Plastic | Zinc die-cast metal, stainless steel or Plastic |

Where our safety switches make the differenceConcrete applications from the industry - simply explained, practical solutions.

Applications

SIB inductive sensors from BERNSTEIN

Efficient safety solutions: Inductive safety sensors from BERNSTEIN AG for ATLAS loader cranes

Applications SMART Safety System

Smart safety technology for the waste disposal industry: Our SRF non-contact safety sensors check whether maintenance flaps are properly closed.

Applications SMART Safety System

Safety technology from BERNSTEIN AG fulfils particularly high safety standards for northern German lifting platforms

More than just a switch.Solutions that take a holistic approach to security.

Safety begins with a reliable product - and ends with a partner who thinks along with you. At BERNSTEIN you get both: a wide range of safety switches and the experience to use them correctly.

Whether series machine, special system or retrofit - we accompany you from the idea to commissioning.

- Broad product range

From mechanical to RFID - suitable for almost any application. - Reliable and durable

Developed for continuous industrial operation - even under harsh conditions. - Fast integration

Compact designs, flexible connections and easy-to-install concepts. - High tamper protection

Non-contact, coded variants that are difficult to bypass - for maximum operational safety. - Practical experience

Over 75 years of expertise in the development of safety solutions. - Personalised advice

Personal support - from product selection to implementation.

Security is a matter of trust. We deliver both - products and partnership.

According to the Machinery Directive, the manufacturer of a machine must ensure that a risk assessment of his machine or system is carried out, for example to determine the safety requirements applicable to the machine.

As part of the risk assessment, hazards emanating from the machine are identified in the risk analysis and their risks are then assessed, taking various aspects into account.

A necessary reduction of the risk can be achieved either by eliminating the hazard or by reducing the aspects. In practice, this usually involves enclosing the danger zone. However, for various reasons (cleaning, maintenance, work process) there must be access to this area.

This access is made possible by a movable guard (usually a door, hood or flap), which must be interlocked. This guard is usually monitored by a safety switch or sensor.

A safety switch or safety sensor monitors the movable guards of a machine or system. They ensure that users cannot open them if a dangerous situation exists. This is because there may still be a risk even if the machine has already been stopped.

A classic example of this is overrunning saw blades. It is imperative that the operator is denied access until the dangerous movement has come to a complete stop.