Predictive maintenance sounds like an Industry 4.0 buzzword at first. However, there is a very practical principle behind it: instead of only repairing machines when they are broken (reactive) or servicing them regularly without a real need (preventive), the ideal maintenance time is calculated in advance thanks to data analysis. And that saves money.

Topic overview

1. How does predictive maintenance work?

1.1. Why is predictive maintenance so valuable?

1.2. Where is predictive maintenance used?

1.3. Predictive vs. conventional maintenance: a brief comparison

2. Predictive maintenance and Industry 4.0

2.1. Our solutions for predictive maintenance

How does predictive maintenance work?

Imagine your machine talking to you. Not in the traditional sense - but via switches and sensors that record data such as temperature, vibration or running time. This condition monitoring continuously provides information that is analysed using algorithms and artificial intelligence.

This is how the system recognises

→ "Attention, the bearings are running hot - something is about to happen here."

→ "This machine has almost reached its target cycles - better wait soon."

The whole process is automated, often in real time, and helps you to avoid production downtimes before they occur.

Why is predictive maintenance so valuable?

Here are a few tangible advantages:

- Avoiding downtime:

Unplanned downtime costs money. Predictive maintenance reduces precisely these downtime risks. - Maintenance on demand:

Instead of rigid maintenance cycles, only intervene when necessary - efficient and resource-saving. - Longer machine service life:

Timely maintenance prevents consequential damage. - More transparency:

All machine statuses at a glance - via dashboards, apps or cloud portals. - Higher system availability:

More production, less downtime - that makes purchasing, technology and management happy.

Where is predictive maintenance used?

This Technology is no longer a topic for the future - it has arrived in mechanical engineering. Examples:

- In production plants where sensors are installed on motors, gearboxes or conveyor belts.

- In older machines (retrofit) that are being upgraded - ideal for companies that don't want to buy everything new straight away.

- In the automotive industry, logistics, packaging technology, rail transport or food production.

If data is available, predictive maintenance can be used almost anywhere - especially where unplanned downtime can be really expensive.

Predictive vs. classic maintenance: a brief comparison

| Maintenance type | Maintenance description | Disadvantage |

| Reactive maintenance | Repair after failure | Production interruption, high costs |

| Preventive maintenance | Maintenance at fixed intervals | Effort even without a specific need |

| Predictive maintenance | Maintenance according to actual machine condition | Initial investment, but quickly profitable |

Predictive maintenance and Industry 4.0

Predictive maintenance is a core component of Industry 4.0 - in other words, networked, digital production. The combination of sensor technology, cloud platforms, artificial intelligence and machine learning creates a system that is constantly learning and predicting with increasing precision when and where maintenance is required.

This is not only exciting for technology enthusiasts - but also for purchasing:

Because fewer breakdowns and targeted use of resources mean clear economic benefits.

Our solutions for predictive maintenance

If you're thinking: "Sounds good - but how do I get started?" - then we have just the thing.

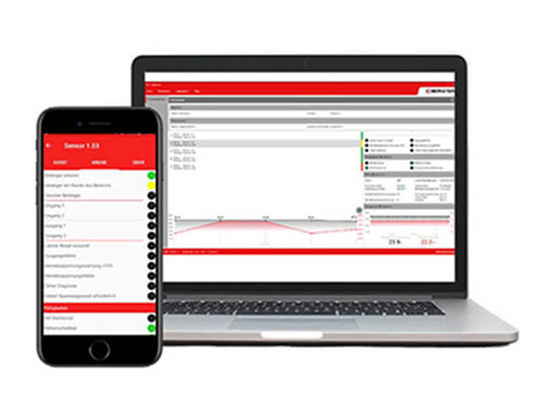

With the Smart Safety System from BERNSTEIN, safety-relevant machine components can be easily integrated into a digital maintenance concept. The system is based on the DCD diagnostic system, which collects status data from connected safety switches and transmits it centrally to a relay. From there, the information can be viewed via a dedicated software both as a mobile app and on a stationary computer.

So you can see at any time

- whether a switch has been triggered,

- how many operating cycles have already been run through,

- whether critical values have been reached,

- and when maintenance is required.

This is predictive maintenance at the touch of a button - even for safety-critical components.

→ Further technical details can be found in the Smart Safety System catalogue (PDF)

Retrofit: Predictive maintenance for older machines

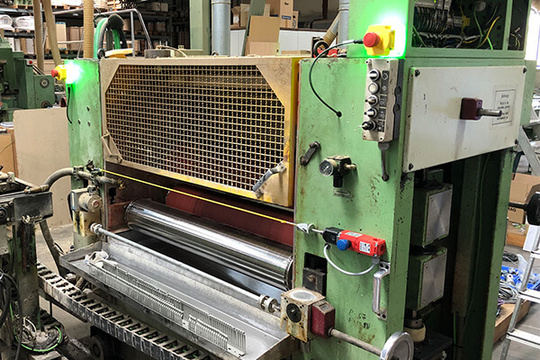

Predictive maintenance can also be implemented for older systems - for example through targeted retrofitting. One example: together with the company zfr control, BERNSTEIN modernised a laminating system from 1996.

The core of the retrofit was the Smart Safety System with DCD diagnostic system, which intelligently networks rope pull switches, non-contact sensors and emergency stop devices. The series connection of all components over around 100 metres now enables efficient status monitoring - including fast fault diagnosis directly on the device.

An otherwise costly voltage drop could be specifically recognised and immediately rectified by transmitting the operating voltage of each device. This saves time and prevents unnecessary downtime - exactly what predictive maintenance is supposed to do for old machines.

Conclusion: Focus on predictive maintenance now

Predictive maintenance is not a fairytale of the future, but a tangible solution to downtime, unnecessary maintenance and inefficiency. Getting started is easier than you might think - and the effect is noticeable.

Want to know how this can work for you?

We'll be happy to help you - whether you're just getting started or already collecting data.