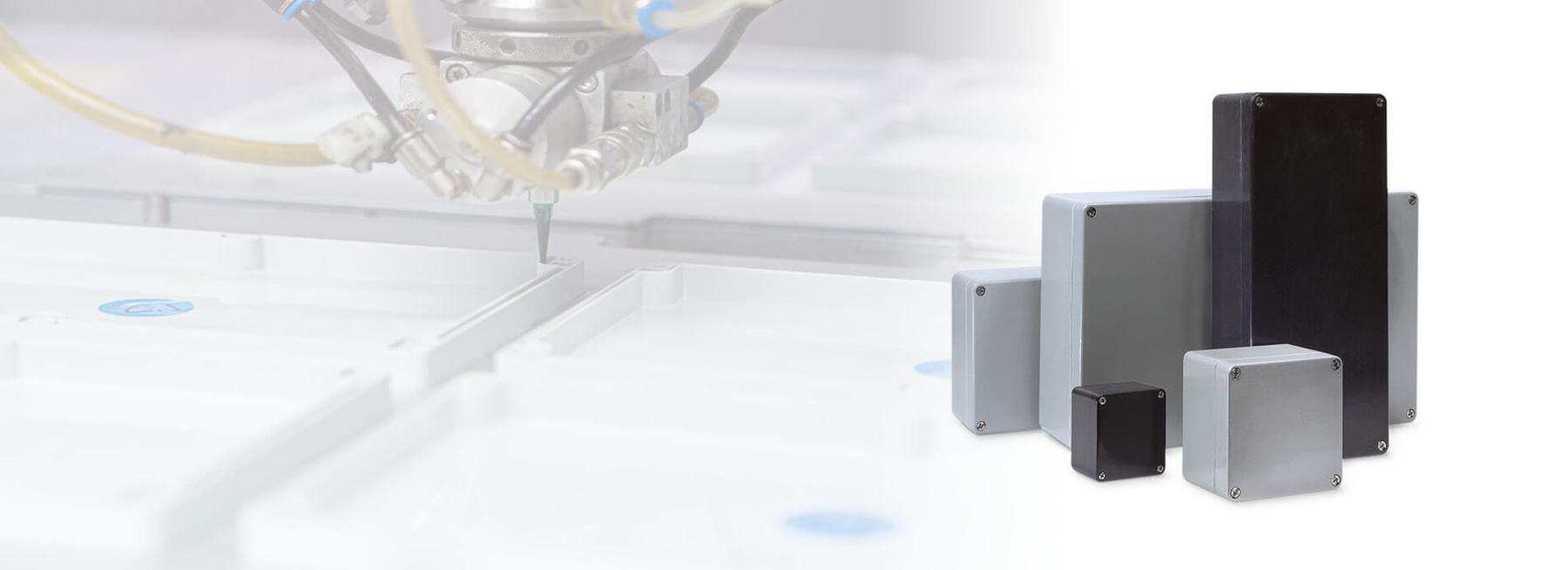

Glass fibre reinforced, flame-retardant and weatherproof - polyester enclosures from BERNSTEIN provide reliable protection against heat, moisture and mechanical stress.

The enclosure solution for demanding applications.

Our polyester enclosures made of glass fibre reinforced plastic (GRP) combine robustness with standard-compliant functionality. They reliably protect your technology from dust, moisture and mechanical stress - even under extreme conditions.

Whether in mechanical and plant engineering, railway technology or in potentially explosive atmospheres: polyester enclosures are the durable, safe and versatile solution for demanding applications.

Jump directly to the right place:

Enclosure variants | Material comparison | Processing options | Advantages | Contact

Polyester enclosures are used for different technical purposes depending on the area of application. BERNSTEIN offers several designs for this purpose – tailored to standard industrial applications as well as to special requirements in railway or explosion protection technology.

Standard polyester enclosures

For mechanical and plant engineering

The standard polyester enclosures are suitable for universal use in mechanical and plant engineering. They impress with their robust design, simple assembly and versatile use in industrial applications.

Railway polyester enclosures

For railway vehicles and railway infrastructure

These enclosures are specially designed for use in railway technology and fulfil increased requirements for fire protection and material behaviour. They are used in railway vehicles and in stationary railway applications.

→ More about railway polyester enclosures according to EN 45545

Every application has different requirements in terms of material, protection class and design. With the CA (aluminium), CT (plastic) and CP (glass fibre reinforced polyester) series, BERNSTEIN offers suitable solutions for a wide range of applications. In the following overview, you can see at a glance how the enclosure types differ.

| Type series | CA (aluminium) | CT (plastic) | CP (polyester) |

| Enclosure material | Die-cast aluminium | Polycarbonate / ABS | Glass fibre reinforced polyester |

| Manufacturing process | Die casting | Injection moulding | Moulding process |

| Protection class | IP66 / IP67 | IP65 / IP66 | IP66 / IP67 |

| Impact resistance | IK08 / IK09 | IK06 / IK07 | IK08 |

| Cover | Screws | Quick-release fastener | Screws |

| Temperature range | -40 to +90 °C (variants with extended temperature ranges available on request) | -35 to +100 °C (variants with extended temperature ranges available on request) | -40 to +100 °C (variants with extended temperature ranges available on request) |

| Approvals | CE, UL, RoHS, ATEX/IECEx | CE, UL, RoHS | CE, RoHS, ATEX/IECEx |

| Optional features | Seawater-resistant versions, EMC versions, Ex versions, alternative sealing material | Transparent cover, EMC versions, alternative sealing material | Ex versions, EMC versions, alternative sealing material |

Our polyester enclosures can be processed in a variety of ways and customised to your application - for example by milling, drilling or integrating pre-assembled components. EMC coatings and special colours are also possible.

In this way, a standard enclosure can be turned into a solution that precisely matches your application in no time at all.

Polyester enclosures from BERNSTEIN are used wherever reliability, protection and adaptability are required. Whether for standard applications, railway projects or hazardous areas, they can be flexibly adapted to different requirements and provide a secure basis for industrial solutions.

✔ Your advantages at a glance

Are you unsure which design is suitable for your application?

We would be happy to assist you in selecting the right polyester enclosure and work with you to develop a tailored solution.