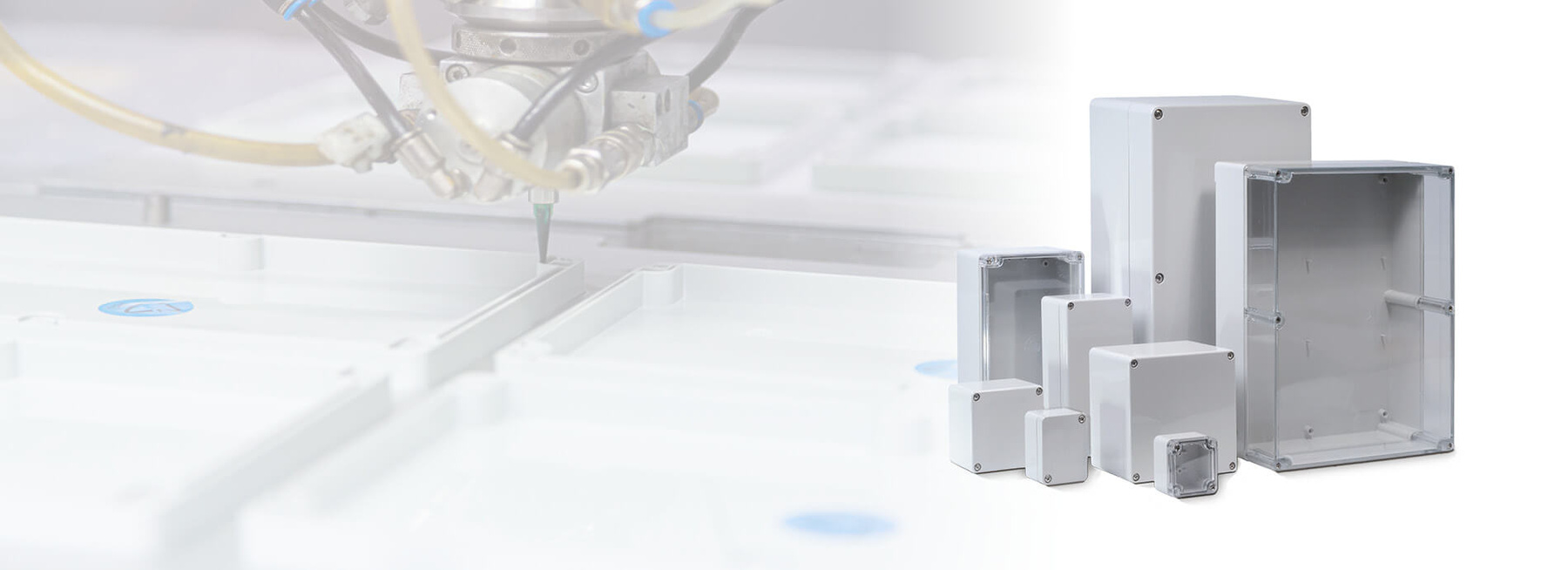

Our polycarbonate enclosures protect what counts - precisely customised, robustly finished and ready for your requirements.

Safety in every application. Flexibility down to the last detail.

Whether dust, moisture or mechanical stress - industrial environments require enclosures that provide reliable protection and can be used flexibly at the same time. Polycarbonate enclosures combine these requirements in an ideal way: They are robust, weatherproof and cleverly designed.

Thanks to their high impact resistance, all-round PUR seal and IP66 protection rating, they also offer optimum protection in outdoor areas. An optional transparent cover allows displays or status lights to be seen without having to open the housing - a clear advantage in automated processes or for regular visual inspections.

With their combination of robustness and functionality, polycarbonate enclosures are a reliable choice for a wide range of applications.

Polycarbonate enclosures are characterised above all by their resistance to environmental influences. The material used is UV-resistant, halogen-free and can also withstand major temperature fluctuations - ideal for permanent indoor and outdoor use.

The IP66 protection rating ensures that neither dust nor strong water jets can penetrate the housing. The protection is complemented by a precisely fitting PUR seal that remains permanently elastic and guarantees a reliable seal - even when repeatedly opened and closed.

Shielded versions are also available for applications with increased EMC requirements. These are equipped with a conductive inner coating and thus provide effective protection against electromagnetic interference.

Thanks to the optional clear cover, the inner workings of the enclosure remain visible at all times - without impairing the protective function. This is an advantage in installations where indicators, indicator lights or displays need to be read regularly.

A plastic enclosure does not have to be confined to one shape. The polycarbonate enclosures in the CT series are designed in such a way that they can be adapted to a wide variety of installation situations and environmental conditions. Whether compact or spacious, with a grey or transparent cover - the right design is easy to find.

Variants with a conductive inner coating are available for special requirements, making the enclosure suitable for use in sensitive EMC environments. Sophisticated details such as integrated fixing cams or additional accessories make mounting easier - regardless of whether the enclosure is used in machines, systems or outdoors.

The result is a polycarbonate enclosure that can not only be integrated, but also thinks along with the application.

Every application has different requirements for interfaces, connections or fastenings. In order to make installation as efficient as possible, polycarbonate enclosures can be customised before delivery - for example with drill holes, cut-outs or markings. This saves time during assembly and reduces sources of error in the process.

A polycarbonate enclosure has properties that make the difference in everyday industrial applications: reliable protection, high material resistance and a design that facilitates maintenance and installation. The combination of function and adaptability pays off where processes need to run smoothly.

Developed and manufactured by BERNSTEIN, the enclosure system is based on decades of experience in industrial enclosure technology - and on the demand to offer practical solutions that work in the long term.

Whether for series production or customised applications - with the right polycarbonate enclosure, well thought-out protection starts right at the selection stage. When it gets more specific, the direct line to the right contact person is just a click away.