ABS enclosuresProtects what counts. Right from the start.

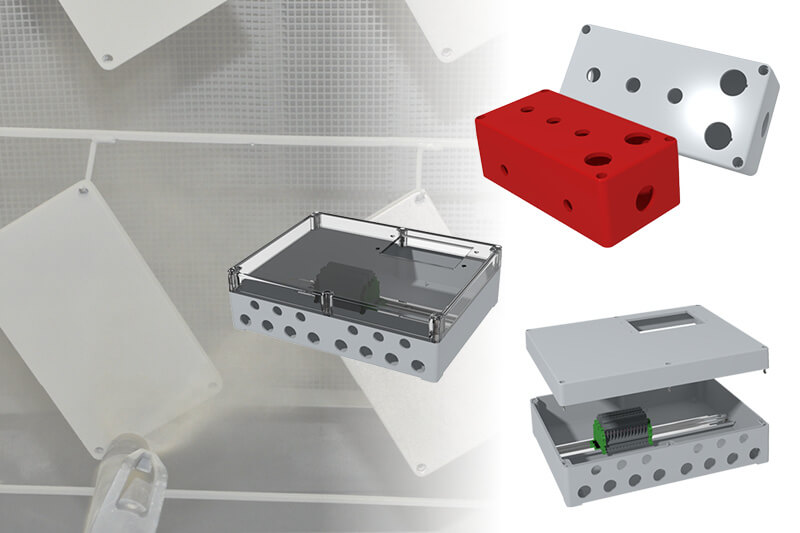

Protect your electronics from dust, moisture, and mechanical stress with robust ABS enclosures from BERNSTEIN. Lightweight, durable, and ready for industrial use, they integrate seamlessly into existing processes.

ABS enclosures directly from the manufacturer

BERNSTEIN develops and manufactures ABS enclosures for the reliable protection of electrical components in industrial applications. Robust materials and precise workmanship ensure permanently stable solutions.

Our ABS enclosures are impact-resistant in accordance with IK07, achieve protection classes up to IP66, and are temperature-resistant from –35 °C to +80 °C. The material complies with flammability class UL 94 HB and is REACH and RoHS compliant.

Integration is straightforward: mounting with wall bracket or top-hat rail, optionally with transparent cover or integrated cable entry.

Because no two projects are the same.Precisely manufactured ABS enclosures for individual requirements.

Our industrial enclosures made of ABS plastic can be customized to suit your specific requirements – with milling, drilling, integrated cable entries, or special mounting solutions. Our machining center creates functional solutions that integrate seamlessly into existing applications.

The result is an enclosure that is technically suitable – well-designed and economically implemented.

ABS enclosures are thermoplastics and are manufactured using the injection moulding process. They reliably protect electrical components from dust, moisture and mechanical stress. ABS plastic is characterised by its low weight, high impact resistance, scratch resistance, chemical resistance and good insulating properties.

Yes, BERNSTEIN offers drilling, milling and other customised adaptations.