When more than 2,000 plastic boxes from the healthcare sector are transported through a logistics centre, cleaned and delivered again every day, every move has to be perfect - and every movement has to be safe. In Horsens, Denmark, DKI Logistics A/S operates a fully automated logistics centre with an area of 20,000 square metres. The robots used work in high-speed mode - precision and safety are essential.

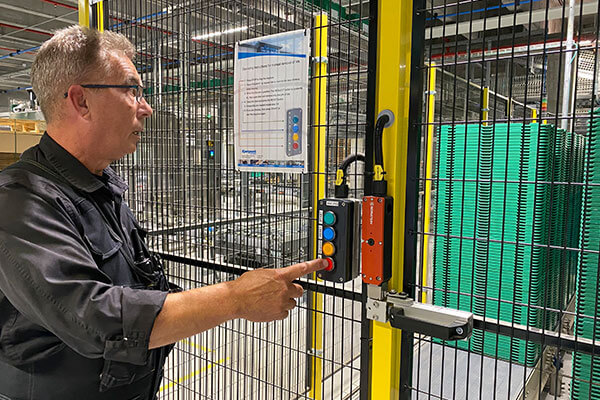

The large robots that carry out high-speed and precision work are each surrounded by a safety fence so that employees do not come into contact with them and possibly injure themselves seriously. If an error occurs or the robot has to be stopped for any other reason, it is important that the safety of the employees remains the top priority. As long as the system is still in motion, access must therefore be denied.

The SLC interlock switch from BERNSTEIN, which is located on the safety gates that provide access to the safety area of a robot cell, ensures precisely this. The SLC keeps the door closed as long as the robot is moving inside. An emergency unlocking device mounted on the front of the SLC enables the safety door to be opened immediately from the outside in an emergency. In contrast, the escape release located on the back of the switch enables immediate opening from the inside in the event of an emergency.

‘For the safety of our team, we have to be able to trust the safety technology,’ says Torben Jensen, Technical Manager at DKI Logistics A/S. "And we do! BERNSTEIN products are reliable, uncomplicated and easy to use. BERNSTEIN is undoubtedly one of our absolute favourite suppliers of safety products. It's quality at a fair price."